Core knowledge

The lyophilization thermodynamics and the formulation excipients

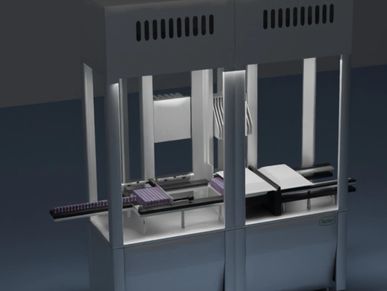

Sterile drugs, the new GMP Annex 1, contamination free freeze dryer loading

The lyophilization thermodynamics and the formulation excipients

Freeze drying (lyophilization) is a thermodynamic process with three main steps:

1.-Freezing: The phamaceutial homogeneous solution is frozen by low temperature, ending in an hetegeogeneous solid, composed by crystaline pure water ice surrounding the concentrated solidified solution (in amorph or crystaline form).

2.-Prymary drying: The crystaline pure ice is removed by sublimation leaving behind the concentrated solution. This sublimation process should not exceed the critical temperature (Tc) of the concentated solidified solution, to avoid reversing its solidification, by regaining water from the crystaline pure ice and becoming again liquid or a rubber solid without enough estructural strenght (and then colapse).

3.-Secondary drying: when the crystaline pure ice has been removed, it is time to reduce the residual humidity at the concentrated solidified solution, to stablish the final residual moisture of the final dried product for an enhanced stability.

The formulation excipients, additional compounds (salts, sugars, alcohols...), neutral to the Active Pharmaceutical Ingredient (API), allows the drug to withstand the stresses caused by the process: concentration (and therefore PH and osmotic) swifts, low temperatures, also improving the stability by avoiding oxidation or degradation, additionally providing structural consitency at the dried product, and finally to withstand the reconstitution, for the final delivery to the patient.

Lyophilization is energetically and cost intensive. It is a slow process, with cycle times typically between one to three days. The parametrization of the process by computational modelization is key for balancing time and cost during the development phases.

Biological drugs, personalized medicine and small batches.

Sterile drugs, the new GMP Annex 1, contamination free freeze dryer loading

The lyophilization thermodynamics and the formulation excipients

Biologicals, are a new category of pharmaceutical molecules that are not synthesized chemically and need biological systems for their production. Its production is mainly made from living cells, making the process delicate. The production batches are small, as genetic diagnosis allows treatments for specific targeted groups of population (personalized medicine).

Research, development and production of of biologics are changing the pharmaceutical ecosystem, involving a wider range of companies, added to the large R&D multinationals and generic manufacturers, it is now required the participation of local companies, CMOs and CDMOs, also biotechnology companies.

Biologicals from blood derivatives, bioengineered vaccines, recombinant proteins, monoclonal antibodies (mAbs) and advanced therapy medicinal products (ATMPs) have been available around the end of 20th century and the beginning of the millennium and have revolutionized therapy and significantly improved the situation of several so-called ‘untreatable diseases’ across all the medical specialties. Biologics are now widely used in routine day-to-day medical practice.

Since the emergence of biologics, cryopreservation (below -80ºC) has been the common storage method for these sensitive, large and complex molecules. Nevertheless, lyophilization it is called to be the alternative, enhancing the logistics, for storage and distribution (not need of low temperatures), also improving and even being the only option for stabilizing some delicate molecules.

The lyophilization thermodynamics and related technology, also the formulation excipients, are being adapted for these new complex and sensitive molecules.

Sterile drugs, the new GMP Annex 1, contamination free freeze dryer loading

Sterile drugs, the new GMP Annex 1, contamination free freeze dryer loading

Classical drugs are organic compounds mostly synthesized in laboratories with a relatively small molecular weight (usually <500 g/mol).

Because its small size, small molecules can be delivered orally to patients, as they can be absorbed by diffusion through the intestinal lining.

Differently, biologicals, with its large and complex structure are normally degraded by the digestive apparatus and need to be supplied parenterally, for example injectables, directly to the blood stream, surpassing all the natural protection barriers of the body, and thus there is the need to produce and deliver them to patients sterile (aseptically).

During its production, pharmaceuticals are purified by filtration and chromatography (in closed circuit), but at the final fill-finish and freeze drying (primary packaging), the product needs to be in open circuit, and consequently the ambient conditions accurately controlled, in Class A cleanroom conditions (with a maximum permitted number of particles at the air (≥ 0.5 μm) per cubic meter of 3.520).

Additionally, the new Good Manufacturing Practices (GMP) Annex 1 is asking for minimizing the human interaction at these conditions (open circuit with vials open or partially open) by the use of automatic systems.

Then the flexibility and small size that the production of biologicals is requiring, also the need of producing pre-clinical and clinical batches in GMP conditions, has made emerge the Single and Ready to Use consumables, that together with the isolator technology (fixed or flexible), lyophilization protective membranes and pilot freeze dryers, are the answer to the new challenges of the pharma ecosystem.

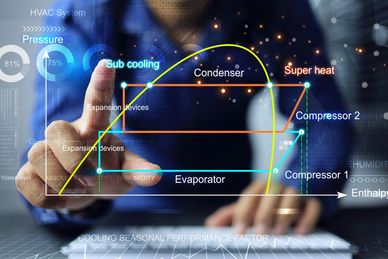

High vacuum systems and low temperature refrigeration

High vacuum and low temperature refrigeration are the main technologies (sciences) behind a freeze dryer. Both of them tightly related; the main vacuum pump in a lyophilizer is the low temperature condenser (-80ºC), trapping/condensing all the vapor molecules coming from the product.

The vacuum level required in a lyophilizer, 0.01mbar (a), is far below other applications in the industry, what makes its vacuum components and manufactured parts very specific, with few vendors and professionals specialized on it.

A cubic centimeter of gas (more or les a dice) at atmospheric pressure, 1000mbar (a), in vacuum, 0.01mbar (a), becomes 100 liters! And the same happens with the volumetric flows and gases speeds, being increased proportionally, making possible to face sonic flows (Mach 1) at the a freeze dryer (choked flow at the condenser connection). Micrometric holes at the vacuum vessel, pipping and fittings, can compromise the vacuum level. The lyophilizer overall leak rate shall be tested periodically, sometimes using an helium leak detector.

Common industrial refrigeration (down to -40ºC) is also above the required -80ºC at a freeze dryer. The low temperatures in a lyophilizer involves including complex systems with different stage compressions and expansions, sometimes involving multiple refrigerants. Additionally, the F-Gas regulation, is limiting the use of synthetic refrigerants with high Global Warming Potential (GWP), making these complex refrigeration systems to be updated. New systems are emerging: using hydrocarbons, compressed air or CO2 .

Every application requires a careful definition of the vacuum and refrigeration systems, selecting the proper vacuum pumps (oil sealed or dry) and compressors (double stage or cascade), also the temperature (PT100 or thermocouple) and pressure (pirani or capacitive) sensors ; for a safe, viable and reliable performance, during the lyophilizer lifecycle.

Steam and H202 sterilization, pressurized vessels regulations

The objective of sterilization is to inactivate microbial contamination, thus turning a non-sterile device into a sterile one.

Sterilization should not be confused with disinfection or sanitization. By definition, sterilization terminates microorganisms (bacteria, viruses or spores). On the contrary, disinfection and sanitization reduce the number of pathogenic organisms to what are considered ‘acceptable’ levels.

In pharma freeze drying mainly two sterilization methods are used: Steam and VHP (Vapor Hydrogen peroxide) sterilization.

Steam sterilization is the most common sterilization method due its reliability, relaying on temperature to destroy microorganisms. Saturated steam (at phase change equilibrium) heated at 121ºC and with a pressure of 2 bar(a), is introduced at the freeze dryer for 30 minutes. The phase change conditions of the steam assures a constant and homogeneous temperature along the different internal parts to be sterilized.

VHP sterilization is a low-temperature (and low pressure) gaseous method of sterilization, relying on the high oxidative behavior of hydrogen peroxide to chemically terminate with the microorganisms. Differently to steam, its homogeneous application is more challenging and requires careful validation. Hydrogen peroxide can be directly boiled in vacuum, or vaporized in air.

Freeze dryers that work under pressurized steam, needs to be designed and manufactured accordingly, reinforced for positive pressures, following the pressurized vessels regulations, as the PED at Europe and ASME at USA.

Including steam sterilization in a freeze dryer increases notably its cost, but these lyophilizers are the most extensively used due its reliability and easy validation.

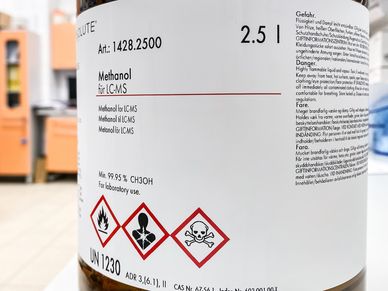

Organic solvents and toxic products, containment barriers and the Atex regulation

During the freeze drying process, pharmaceuticals need to be in open circuit, what entail a risk as some of its components can be toxic and/or flamable, including the Active Pharmaceutical Ingredient (API), that can be High Potent (HAPI).

Normally, during the initial filling and freeze dryer loading, as the product is diluted in water, has low toxicity risc for the operators, but some of its organic solvents, if present in high concentrations, can evaporate creating an explosive atomsphere.

Generally speaking, a freeze dryer, as a vacuum equipment, can avoid the presence of oxigen, an element necesary together with the flamable agent and the spark, to cause an explosion. But at the first pump down for evacuating the vacuum chamber, some evaporated solvent vapors in the presence of ambient oxigen, can entail an explosion risk, limited to the internal parts in contact with the mixture solvent + atmospheric air.

After the freeze drying process, the product is a dried cake, fragile and volatile. Specially during the final cycle pressurization and during the drying, some small quantities of product powder is draged out of the product and can be externally dropped at the vials and floating at the air, having higher toxicity risc for the operators.

The concentration of flamable solvents and/or toxic compounds, also the degree of toxicity , in liquid and dried form, defined by the Ocupational Exposure Bands (OEBs), will set the strategy for a safe lyophilization operation.

Aspects as batch size, lyophilizer loading system, containment (fixed or flex isolator, CRabs or ORabs), clean room clasification, the usage of protective membranes, freeze dryer components ATEX zone 1 and zone 2, are considered in the Risk Assesment for the best adjusted solution for each application.

Subscribe

Periodically we are pubishing our works: topics of interest, white papers and scientific papers. Take a look to our publications section. When subscribed to our site, you will not be missing any of our new releases.